Kobelco introduces completely New cooling system for SR Excavators

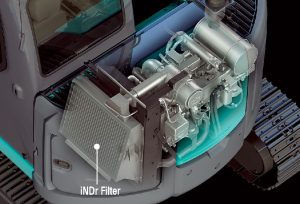

Kobelco has reached into the future and pulled out an entirely new cooling system for their hydraulic excavators. They call it iNDr, or integrated noise and dust reduction cooling system. And it’s aptly named. This new proprietary technology revolutionizes the way Kobelco excavators accomplish engine cooling, and you’ll like the results.

You know the problems associated with cooling all too well.

You know the problems associated with cooling all too well.

In many ways, your excavator’s cooling system is a necessary evil. It’s inherently counter-productive. On the one hand, you can’t live without some kind of cooling – it’s essential to keep your engine from overheating. But traditional cooling systems depend on air movement, using a fan to push “wind” through the radiator, oil cooler and intercooler.

And while the concept is good, the execution leaves something to be desired, because your equipment doesn’t get up enough speed to create that wind. Usually it’s more or less stationary.

This is not a formula for efficiency or effectiveness. Yet up till now, it’s been the only system available.

Efforts to fix the problem have centered on the only apparent option – increasing the size of the components to make more wind. Bigger fan. Bigger radiator. Bigger oil cooler and intercooler. But the construction marketplace is demanding smaller machines, that can’t accommodate all these larger parts. Customers want less – smaller size, shorter swing radius, less noise, less time-consuming maintenance.

Unfortunately enlarging the components not only creates machine size issues, it creates more noise as well as the opportunity to draw more dirt and dust into the engine. More clogging, less productivity.

It’s a conundrum.

Kobelco excavators are changing all that.

The company’s top R&D people spent six years pondering an entirely new approach to engine cooling. Their answer? A closed duct system that has just one intake and one exhaust port, with an offset “wind pathway” in between. This system provides far greater air control, in turn controlling sound, dust and heat far more effectively.

The angled pathway inside the system essentially creates a series of baffles that lock in noise rather than allowing it to escape. Tests have shown that Kobelco excavators using this cooling system produce as much as 10 decibels less noise than other machines. That’s a significant difference – one you’ll notice immediately, because surprisingly, cooling systems account for a substantial portion of the excavator’s overall noise output.

This sound reduction puts Kobelco excavators so far below industry noise regulations that the manufacturer has coined a new term for it – “ultimate-low-noise.”

This sound reduction puts Kobelco excavators so far below industry noise regulations that the manufacturer has coined a new term for it – “ultimate-low-noise.”

The system efficiently fends off dust, too, with a solution that makes maintenance a snap. A specially designed filter features a wide 60-mesh screen and accordion structure, and it’s placed right at the intake port, to capture dust before it can enter the system. Your engine is far less likely to overheat, because it’s better protected, no matter how much dust you kick up on the job. One filter, one location. And all you have to do is eyeball during your startup inspection, to see if it’s needs replacement.

Simple enough….

Kobelco excavators with an integrated noise and dust reduction cooling system are breaking new ground, in more ways than one.