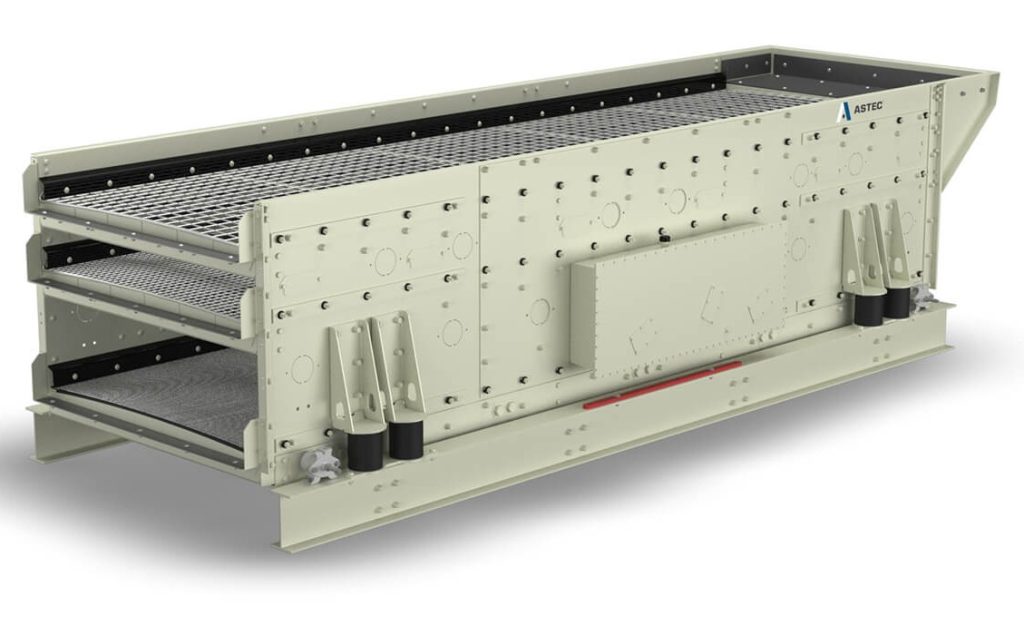

POWER AND PRECISION COMBINE IN THE ALL-NEW ASTEC VARI-FREQUENCY HORIZONTAL SCREEN

ASTEC Industries has once again raised the bar in material processing technology with the launch of its new Vari-Frequency Horizontal Screen, a groundbreaking addition to its family of high-performance screening solutions.

Engineered to provide superior adaptability, efficiency, and throughput, the ASTEC Vari-Frequency design allows operators to fine-tune vibration frequency to match the specific characteristics of the material being processed — ensuring optimal performance across a wide range of applications.

Available through Tracey Road Equipment, this innovation underscores ASTEC’s ongoing commitment to helping producers work smarter, reduce downtime, and achieve more consistent results across every load.

Game-Changing Versatility — Astec’s New Vari-Frequency Horizontal Screen

ASTEC Industries announces the launch of its groundbreaking Vari-Frequency™ technology implemented on our 6203 LP Horizontal Screen, a next-generation solution built to boost screening performance. The new design minimizes blinding and maximizes uptime, giving producers a smarter, more reliable way to keep processing material.

What Is the ASTEC Vari-Frequency Horizontal Screen?

The ASTEC Vari-Frequency Horizontal Screen is a state-of-the-art screening solution that gives producers unprecedented control over their material processing.

Unlike conventional fixed-speed horizontal screens, this system allows operators to adjust vibration frequency on demand, ensuring ideal separation, reduced blinding, and higher throughput — no matter the material type or gradation.

Key Specifications:

Adjustable Frequency Range: Fine-tune vibration from low to high RPM for variable materials.

Optimized Efficiency: Match screen performance to particle size and feed consistency.

Enhanced Durability: Built with ASTEC’s heavy-duty design for long-term reliability.

Compatibility: Designed for both portable and stationary applications.

This adaptability makes it the ideal choice for aggregate producers, recyclers, and asphalt operations seeking to maximize precision and uptime in changing material conditions.

The Technology Behind Vari-Frequency

Traditional horizontal screens operate at a fixed vibration frequency, meaning they perform best under specific material conditions — often forcing operators to compromise between speed, accuracy, and product quality.

The ASTEC Vari-Frequency system eliminates that compromise. Its variable drive control allows operators to adjust vibration speed in real time, optimizing performance for every feed type — from wet, sticky clay-based material to dry aggregates.

How It Works:

Adjusting vibration frequency changes how material stratifies across the deck.

Lower frequencies provide more aggressive material movement, ideal for coarse screening or wet conditions.

Higher frequencies increase fine material separation and improve accuracy for dry feeds.

This flexibility reduces downtime, prevents clogging, and improves overall screening quality.

In essence, one screen can now do the work of multiple machines, adapting instantly to jobsite needs.

Designed for Performance and Reliability

As with every ASTEC product, the Vari-Frequency Horizontal Screen is built for real-world demands. From quarry operations to asphalt production, it provides the durability and uptime that producers expect from the ASTEC name.

Performance Features Include:

Precision Control System: Easy-to-use interface for fine-tuning vibration speed.

High-Capacity Deck Design: Maximizes screening area and material flow.

Rugged Frame Construction: Built with reinforced side plates for long service life.

Maintenance-Friendly Layout: Simplified access points for fast adjustments and inspections.

Combined, these features deliver consistent material quality, longer wear life, and lower total cost of ownership — making the Vari-Frequency screen an investment in long-term efficiency.

Applications Across Industries

The versatility of the ASTEC Vari-Frequency system makes it valuable across multiple segments of the material processing industry:

| Industry | Application | Key Benefits |

|---|---|---|

| Aggregates | Screening sand, gravel, and crushed stone | Adjust for moisture and particle size changes |

| Asphalt Production | Screening recycled asphalt and RAP | Improves accuracy and reduces contamination |

| Mining & Quarrying | Sorting ore and overburden | Optimizes performance for varying rock hardness |

| Recycling | Processing construction and demolition debris | Handles inconsistent materials with precision |

| Contract Crushing | Mobile or stationary screening setups | Reduces need for multiple screens on-site |

This multi-industry flexibility helps operators streamline their equipment lineup and achieve maximum utilization from a single unit.

The Benefits of Vari-Frequency Technology

1. Unmatched Versatility

Handle a wider range of materials with fewer adjustments or machine swaps.

2. Improved Product Quality

Fine-tune frequency for consistent, high-quality end products.

3. Reduced Downtime

Minimize screen clogging, material buildup, and maintenance interruptions.

4. Lower Operational Costs

Increase screen efficiency while extending wear part life.

5. Sustainable Efficiency

Energy-efficient motor controls reduce power consumption without compromising performance.

By combining control, performance, and reliability, ASTEC Vari-Frequency Horizontal Screens are redefining what’s possible in modern material processing.

Built by Astec, Backed by Tracey Road

At Tracey Road Equipment, we’re proud to partner with ASTEC — a name synonymous with innovation and durability. Our team offers expert guidance, factory-certified service, and full parts support to help you integrate ASTEC Vari-Frequency screening technology into your operation seamlessly.

Whether you’re optimizing an existing plant or planning a new setup, Tracey Road can help you choose the right screen configuration and keep your material flow running efficiently all season long.