SPEED SHORE SAFETY ESSENTIALS: PROTECT YOUR CREW IN EVERY TRENCH

When it comes to working in and around excavations, trench safety is more than a best practice—it’s a necessity. At Tracey Road Equipment, we proudly offer Speed Shore trench shoring systems, which are designed to help prevent collapses, protect workers, and keep jobsites OSHA-compliant. Whether you’re trenching for utilities, foundations, or municipal work, safety should always come first.

In this post, we’ll explore 8 essential trenching safety tips to help your crews stay protected and productive.

Every Second Counts: Work Smarter Below Ground

Speed Shore Corporation, the industry leader in the design and manufacture of innovative trench safety equipment, also leads the industry in providing excavation safety training. Speed Shore currently offers a 1-day Excavation Safety program, which is available monthly on an open enrollment basis at our Houston headquarters, or on a contract basis anywhere in the United States. The course curriculum is designed to meet the training requirements for the “Competent Person” as stipulated by the OSHA Standard for Excavations.

1. Always Use the Right Shoring Equipment

Not all trenches require the same protection. Choosing the correct Speed Shore trench box, hydraulic shoring system, or aluminum shield based on soil conditions, depth, and project duration is critical. Make sure your equipment is designed and rated for the trench dimensions and conditions.

2. Pre-Job Inspection Is a Must

Before breaking ground, inspect the area for:

- Soil type and moisture content

- Nearby traffic, utilities, or structures

- Evidence of previous excavation activity

Use this information to determine the appropriate protective system and ensure the job meets OSHA standards. Make sure to also review the tabulated data sheet for the trench box you will be using to make sure it is designed to handle your soil conditions. These sheets can be found at speedshore.com.

3. Assign a Competent Person

OSHA requires that a competent person be on-site to identify hazards, evaluate trench stability, and make adjustments as needed. This individual should be trained in soil classification, protective systems, and hazard recognition.

4. Monitor for Environmental Hazards

Rain, vibration, or nearby equipment can change trench conditions in an instant. Monitor the trench frequently throughout the day, especially after:

Heavy rainfall

Frost or thaw conditions

Vibration from nearby machinery

Make sure Speed Shore systems remain properly positioned and secure.

5. Provide Safe Entry and Exit Points

Ladders or ramps must be located within 25 feet of all workers in a trench. Don’t rely on natural steps or makeshift ladders. Safe access and egress are mandatory and must be maintained throughout the job.

6. Keep Materials Away from the Trench Edge

Spoil piles, tools, and heavy machinery should be kept at least 2 feet from the edge of the trench. This helps prevent materials from falling in and adds stability to the trench walls.

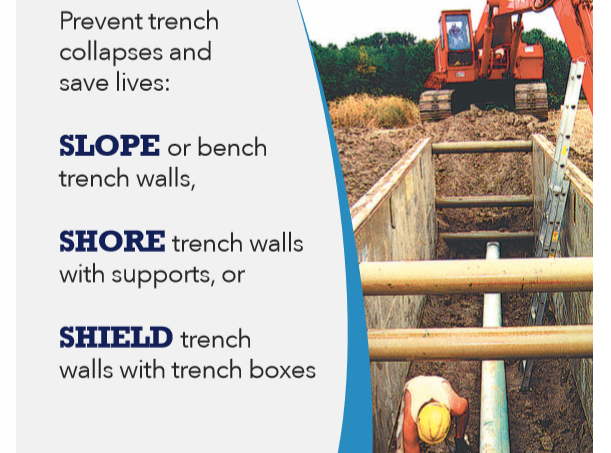

7. Use Protective Systems Every Time

No trench is too short or shallow to skip protection. Collapses can happen in trenches less than 5 feet deep. Speed Shore offers modular aluminum systems, hydraulic shoring, and lightweight shields that make protection fast and efficient.

8. Train and Refresh Regularly

Even experienced crews need safety refreshers. Make trenching safety part of your toolbox talks and ongoing training. Reinforce best practices, review recent near-misses, and update workers on new Speed Shore equipment or OSHA rules.

Bonus Tip: Partner with Experts

Choosing the right shoring system isn’t always straightforward. That’s why working with a trusted dealer like Tracey Road Equipment gives you access to expert recommendations, training support, and compliant solutions from Speed Shore.

Stay Safe. Stay Protected.

Trench collapses are one of the most dangerous hazards in construction. But with the right planning, equipment, and training, they are also one of the most preventable. Trust Speed Shore and Tracey Road Equipment to help you keep your crews protected and your jobsites running smoothly.