When you install properly matched SwapLoader Sub-Frames, you get secure hook-lift compatibility, durability, and performance in every lift and dump operation. Designed with heavy-duty materials, precise hook heights, and accessory flexibility, these sub-frames are foundational to reliable hoist systems. Contact Tracey Road Equipment today to spec the right Sub-Frame series, review options, and ensure maximum uptime on your hook-lift setups.

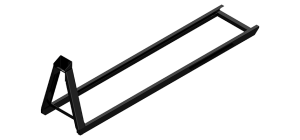

SwapLoader Sub-Frames

Let Us Do the Heavy Lifting

SwapLoader Sub-Frames are purpose-built steel frames integrated into containers or bodies to ensure full compatibility with SwapLoader hook-lift hoists. Whether you’re using 100, 200, 300, or 400 Series systems, these sub-frames support reliable connection, proper hook engagement, and secure body mounting.

Other Equipment

Choose your model

100 Series Sub-Frames

| Hook Height | 35-5/8″ |

| Sub-Frame Length | 10′-18′ |

| Weight | 367 – 511 lbs |

| Download Brochure | |

200 Series Sub-Frames

| Hook Height | 53-7/8″ |

| Sub-Frame Length | 10′-22′ |

| Weight | 686 – 1,090 lbs |

| Download Brochure | |

300 Series Sub-Frames

| Hook Height | 35-7/8″ |

| Sub-Frame Length | 12′-22′ |

| Weight | 805 – 1,140 lbs |

| Download Brochure | |

400 Series Sub-Frames

| Hook Height | 61-3/4″ |

| Sub-Frame Length | 12′-22′ |

| Weight | 1,200 – 1,410 lbs |

| Download Brochure | |

Why Choose SwapLoader Sub-Frames?

Ensures precise hook height and alignment for smooth operation with SwapLoader hoists.

Built with durability in mind: powder-coat finish, heavy-gauge longsills, rugged lift bars, and A-frame or heavy-duty bar construction depending on series.

Wide range of sizes—various lengths (10′ to 24′), hook heights (35 5⁄8″, 53 7⁄8″, 61 3⁄4″) and rail widths to match your truck model and container size.

Fully compatible accessories (lift bars, A-frames, hook guards, rollers) let you tailor the setup for your container or body.

Sub-Frame Series Overview

Here are some of the main series and their key dimensions:

| Series | Hook Height | Lift Bar Diameter | Longsill Size | Typical Lengths / Models |

|---|---|---|---|---|

| 100 Series | 35 5⁄8″ | Ø1-1⁄4″ | 5″ longsills | 10′-18′, Models like SL-160, SL-212, SL-214, ST-1614 etc. |

| 200 Series | 53 7⁄8″ | Ø1-3⁄4″ | 6″ longsills | Fits SL-220, SL-222, etc. |

| 300 Series | 53 7⁄8″ | Ø2-1⁄2″ | 6″ longsills | Heavy-duty applications. |

| 400 Series | 61 3⁄4″ | Ø2-1⁄2″ | 8″ longsills | Larger containers and heavier hoists. |

Accessories & Related Parts

Lift Bars & Hook Guards

A-Frame braces for front structural support

Sub-frame rollers & mounts for body support

Finish options include powder coating; top longsill areas should be inspected/covered to avoid surface rust.

A SwapLoader sub-frame is the steel frame integrated into the container or body that interfaces with the hook-lift hoist. It ensures correct hook height, alignment, and enables secure lifting/dumping without misalignment or damage.

Match hook height, truck and hoist model, container length, and required durability. For instance, use the 100 Series for lower hook heights and smaller bodies; the 400 Series for larger containers with higher clearances.

No—basic sub-frames typically exclude body rollers, brackets, or hook guards. These are ordered separately to suit your specific needs.

Keep finishes protected (especially longsills), inspect lift bars and hook guards for wear, grease any pivot or moving parts, and ensure that rollers & mounts are aligned correctly to avoid excessive wear.

SwapLoader offers robust technical support, parts availability, and manuals. Warranty specifics can depend on model and usage—consult with your Tracey Road Equipment rep for full details.