Detroit Axles deliver the performance, durability, and efficiency modern fleets demand. From sharper steering capabilities and precision handling to robust rear-drive and tandem configurations, these axles are a foundational piece of the integrated Detroit powertrain suite. Maximize uptime, payload, and reliability—contact Tracey Road Equipment today to spec your next truck with Detroit Axles.

Detroit Axles

Ride on Detroit® Axles for Unmatched Stability and Reliable Precision

Experience unmatched durability and precision with Detroit Axles—purpose-built steering, single-rear, and tandem-rear axles crafted to exceed the toughest demands in trucking. Fully integrated into the Demand Detroit® ecosystem, each axle is designed, machined, and assembled in Detroit, Michigan to deliver industry-leading performance for Freightliner and Western Star trucks.

Choose your model

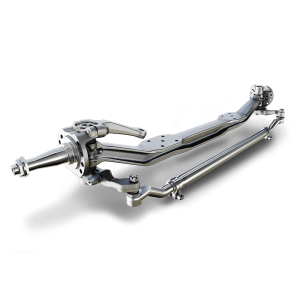

Front Steer Axles

| Weight Rating – Model 2 | 6,000 – 8,000 lbs |

| Weight Rating – Model 3 | 8,000 – 14,700 lbs |

| Weight Rating – Model 5 | 16,000 – 20,000 lbs |

| Download Spec Sheet | |

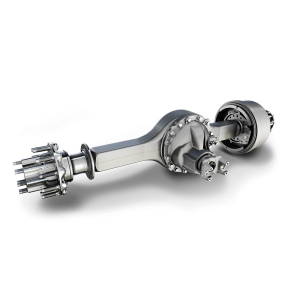

Single Rear Axles

| Weight Rating – Model 2 | 13,000 – 19,000 lbs |

| Weight Rating – Model 4 | 17,500 – 23,000 lbs |

| Weight Rating – Model 6 | 20,000 – 23,000 lbs |

| Download Spec Sheet | |

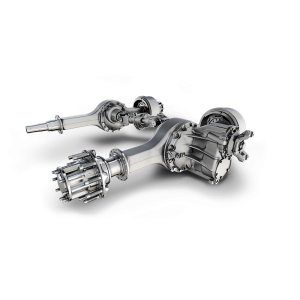

Tandem Rear Axles

| Weight Rating | 34,000 – 44,000 lbs |

| Available Ratios | 2.16 – 3.23 |

| Applications | Multiple Industries |

| Download Spec Sheet | |

Why Choose Detroit Axles?

Steer Axles: Maneuverability and Strength

Cut corners confidently with up to 55° steering angle, thanks to a lightweight I-beam design that boosts payload capacity.

Needle bearings and friction-thrust knuckles significantly reduce wear, enhancing steering precision and durability.

Built for long-term reliability and lower maintenance costs, backed by OEM compatibility.

Single-Rear Axles: Efficient Power Transfer

Engineered for higher torque, quieter operations, and increased payload, Detroit single-rear axles deliver performance with minimal upkeep.

Precision-cut ring and pinion gears ensure smooth power delivery and longer gear life.

Tandem Rear Axles: Heavy-Duty Excellence

Built for heavy-duty applications, with weight ratings up to 46,000 lb, and optimized for both on-highway and vocational use.

Engineered with a Topoid axle design that reduces driveline vibration and increases drivetrain longevity.

Axle Lubrication Management 2.0 (ALM2) ensures effective lubrication and enhances fuel efficiency.

Benefits at a Glance

Lightweight Builds — Heavier payloads enabled through advanced axles that shed unnecessary mass.

Reduced Maintenance — Engineered with durable components that extend service intervals and reduce downtime.

Smooth Power Delivery — Precision-machined components and ALM2 reduce operational noise and energy loss.

Seamless Integration — Axles designed to work seamlessly with Detroit engines, DT12® transmissions, and Detroit Connect® telematics to optimize fleet performance.

They feature up to a 55° wheel cut, lightweight I-beam construction, and needle-bearing technology—all designed for superior maneuverability and durability.

Yes—the single-rear axle models are built for higher torque scenarios with precision gearing and easier maintenance for long-term service life.

The Topoid offset design and ALM2 lubrication system reduce vibration while improving fuel efficiency and gear lifespan.

Absolutely. These axles are engineered to align with Detroit powertrains—working in concert with engines, transmissions, and telematics for optimized performance.

Detroit axles are engineered, machined, and assembled in Detroit, Michigan, in the same facility where Detroit engines and transmissions are built—ensuring consistent quality and alignment across components.