FEEDING THE BEAST: CHOOSING THE RIGHT MACHINES FOR YOUR ASTEC CRUSHING OPERATIONS

When it comes to maximizing productivity in Astec crushing operations, your feed equipment plays a critical role. The choice between an excavator and a wheel loader isn’t just about preference — it’s about optimizing production flow, reducing fuel costs, and maintaining consistent material feed to your Astec crushers and screens.

At Tracey Road Equipment, we help contractors find the right balance between power and precision with equipment from Liebherr, Hitachi, Hyundai, Kobelco, and Astec — delivering a complete, efficient crushing setup built for performance and reliability.

Choosing Between Excavators and Wheel Loaders for Your Astec Crusher

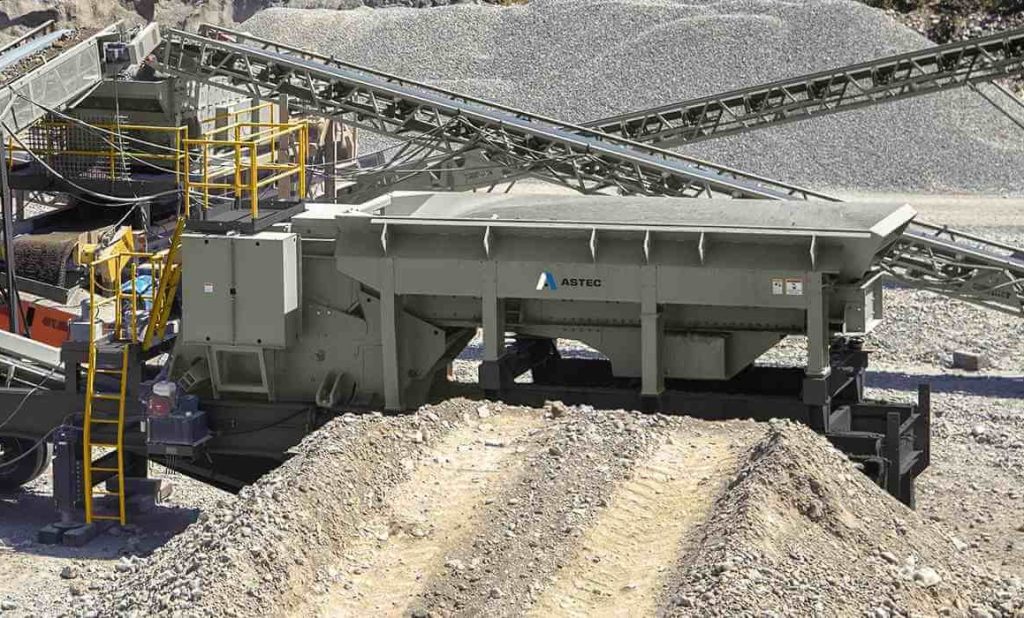

Unlock superior efficiency and flexibility in your aggregate and recycling operations with Astec Mobile Screens and Crushers. Designed for rugged job sites and rapid deployment, these mobile systems deliver high-performance crushing and screening in one integrated solution. Engineered with innovation and durability at the forefront, Astec Mobile Screens and Crushers streamline your production process—boosting throughput, minimizing downtime, and reducing overall operating costs.

The Role of Feed Equipment in Crushing Operations

Efficient material feeding ensures that your Astec crushers run at peak performance. Whether you’re running a mobile impact plant or a stationary jaw and cone setup, consistent feed flow helps prevent downtime, reduces wear, and improves final product quality.

Your choice between an excavator or a wheel loader depends on:

The layout of your crushing site (mobile vs. stationary)

The distance between stockpiles and crusher feed hoppers

The type and density of material being processed

Cycle times, fuel efficiency, and operator visibility

Matching your feed machine to your Astec crushing system ensures smooth material flow and improved overall productivity.

Excavators: Precision and Reach

For stationary or compact crushing sites, excavators are often the best choice for controlling feed into Astec jaw or cone crushers. Their ability to reach into hoppers and regulate material flow makes them ideal for maintaining consistent throughput.

Advantages of Using Excavators:

Precision control over material flow and feed rate

Superior reach for loading high or offset hoppers

Ideal for confined sites where loaders can’t maneuver

Efficient fuel use with reduced travel time

Recommended Models for Astec Crushing Sites:

Liebherr R 945 – Long-reach stability and superior digging power

Hitachi ZX350LC-7H – Smooth hydraulics for fine feed control

Hyundai HX380A L – Load-sensing efficiency and real-time telematics

Kobelco SK350LC-11 – Exceptional balance and fuel efficiency

When precision and consistency matter most, an excavator ensures your Astec crushing spread stays fed, efficient, and steady.

Wheel Loaders: Speed and Mobility

For larger, open-site operations or mobile setups, wheel loaders provide the versatility and speed to keep up with demanding Astec crushing and screening spreads. Their large bucket capacity, fast cycle times, and ability to manage multiple material piles make them the go-to choice for high-output operations.

Advantages of Using Wheel Loaders:

Fast load-and-carry cycles between stockpiles and crushers

Ability to handle multiple materials in one operation

Excellent visibility and operator comfort for long shifts

Versatility for site cleanup, stockpiling, and loadout

Recommended Models for Astec Crushing Support:

Liebherr L 550 XPower® – Low fuel burn, high torque, and hydraulic precision

Hitachi ZW370-6 – Built for heavy production with responsive handling

Hyundai HL960A – Rugged reliability for quarry and aggregate environments

In mobile Astec crushing setups, wheel loaders excel at handling multiple feed points while maintaining high production efficiency.

Matching Equipment to Astec Crushers

Astec’s lineup of mobile and stationary crushing equipment is engineered for flexibility, durability, and productivity. Whether it’s a jaw crusher for primary reduction, a cone crusher for secondary crushing, or a screening plant for final sizing, the right feed machine ensures the system operates at peak efficiency.

Example Equipment Pairings:

Astec FT4250CC Impact Crusher + Hyundai HL960A Loader: High-speed crushing and loading for asphalt and recycling.

Astec GT125 Jaw Crusher + Liebherr R 945 Excavator: Balanced control for precision feed and reduced wear.

Astec FT300 Cone Crusher + Hitachi ZX350LC Excavator: Efficient cycle times and consistent feed flow.

The synergy between the loader or excavator and the Astec crushing spread determines your system’s true production capacity.

Pro Tip: Consider Hybrid Setups

Many high-production sites use both excavators and wheel loaders in tandem. Excavators feed the crusher directly while loaders manage stockpiles, remove overs, or transport finished material. This approach ensures continuous flow while keeping cycle times efficient.

The Tracey Road Advantage

As your trusted Astec crushing and material handling partner, Tracey Road Equipment offers complete support — from machine selection to setup, service, and operator training. We carry:

Astec Crushers, Screens, and Stackers

Liebherr, Hitachi, Hyundai, and Kobelco excavators and loaders

Parts, attachments, and field service support across NY and PA

Whether you’re upgrading an existing site or building a new crushing spread, Tracey Road can help you create a customized Astec crushing solution to meet your production goals.